Self-cleaning air filter

Key words:

Product category:

Product Details

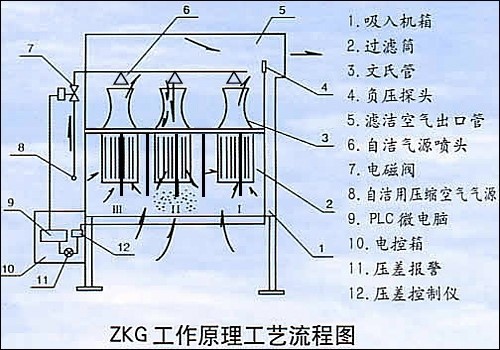

Air passes through the filter cartridge, and due to the combined effects of gravity, inertial diffusion, static electricity, and contact retention, dust settles and accumulates on the filter element.

Clean air is sent out through the outlet after passing through the Venturi tube.

- Self-cleaning process

The dust on the air filter element is automatically controlled by a microcomputer to backflush the filter cartridge in sequence, based on a timed or differential pressure method.

The settled dust particles are blown off into the atmosphere, with only one group (six) of filter cartridges undergoing the self-cleaning process at a time, with an interval of30seconds.

Other filter cartridges remain in normal filtering operation, and the filter operates as usual.

The self-cleaning air filter draws in ambient air. When the air passes through the high-efficiency filter cartridge, dust is retained on the outer surface of the cartridge due to gravity, static electricity, and contact.

The purified air then enters the clean air chamber.

The control system of the equipment controls the backflushing self-cleaning based on the set time program and differential pressure value program. The backflushing self-cleaning system clears

the dust from the filter cartridge, achieving automatic cleaning and maintenance.

The air outlet system plays a role in transmitting clean air, and the clean gas entering the clean air chamber is sent to the required

work area under the action of the fan.

Main technical parameters

- Inlet temperature:Normal temperature

- Initial pressure difference <150Pa, final pressure difference1200Pa

- Processing air volume:1~600Nm3/min

- Filtration accuracy:≥1u(99.99%)

- Backflushing medium: Compressed air

- Working mode:PLCorDCSFully automatic, continuous operation

- Backflushing gas consumption:0.2m3/min;

- Filter cartridge safety vacuum degree:≤-5kpa

- Filtering material: Imported brand fiber filter material

Special specifications can be designed and manufactured according to user requirements.

Product Consulting

Please post your suggestions below and leave a valid contact information so that we can provide timely feedback. Thank you very much.

National unified service hotline

Sales Phone:+868922631278(Mr. Wong)

E-mail:18922631278@163.com

Address: 6868 Zhuhai Avenue, Hongqi Town, Jinwan District, Zhuhai City

Sweep the attention to us

WeChat Public Number

Copyright©2024 Guangdong Global Purification Technology Co., Ltd. Website:www.300.cn SEO [ Privacy Policy ] DigitalCard